Polytetrafluoroethylene PTFE Teflon Flash of Genius or Lucky Accident?

WhatisPTFE?

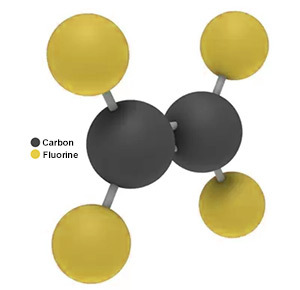

WhatisPTFE?- PTFE the acronym for polytetrafluoroethylene, created quite by accident has become one of mankind's most revolutionary inventions. Polytetrafluoroethylene is a synthetic chemical compound best defined as any polymer, plastic or resin having the formula (C F), prepared from tetrafluoroethylene --a colorless, water soluble, flammable gas.

- Noted for its slippery, nonsticking properties polytetrafluoroethylene (PTFE) is most commonly associated with cookware and products under the 1945 Kinetic Chemicals patented trademark Teflon®. While this revolutionary chemical compound opened the door in the retail market for cookware, it has blown the doors off of industrial and technological applications. What is so remarkable is this door of serendipity opened quite by accident at the DuPont labs in 1938.

History of Polytetrilfluoroethylene (PTFE)

- In 1938-, while working for DuPont Corporation in New Jersey, Chemist Dr. Roy Plunkett was attempting to make a new chlorofluorocarbon refrigerant. When he and his associates were checking a frozen, compressed sample of tetrafluoroethylene they discovered that the sample had spontaneously polymerized into this white, waxy solid form later called polytetrafluoroethylene (PTFE).

- According to the DuPont Corporation," PTFE is inert to virtually all chemicals and considered the most slippery material in existence. These properties have made it one of the most valuable and versatile technologies ever invented, contributing to significant advancements in areas such as aerospace, communications, electronics, industrial processes and architecture."

Industrial Applications of PTFE

- Today, PTFE is used widely in many industries including, but not limited to:

- Petrochemical and Chemical Processes.

- Because of the chemical inertia and resistance to corrosion ofPTFE it is the advanced technology of choice for seals, rings, gaskets, washers, vessel linings, pump interiors, spacers, dip tubes and well-drilling components.

- Electrical Applications.

- Since PTFE is one of the best insulators known, it is used in wire and cable wrap, and to separate conductive surfaces in capacitors. In thin sections, it will insulate to 500 volts per mil.

- Semi-Conductor Industry.

- PTFE is inert with an operating temperature range from minus 180° Celsius to 260° Celsius. It is the material of choice for chip manufacturing, cabling materials, fluid handling components, filters, sensors, piping, tanks and containers. The components are used in the semiconductor industry for transport and handling of aggressive, ultrapure fluids. Applications include piping, fittings, valves, wafer carriers, linings for storage tanks and vessels, sinks for wet benches, fluidcontainers, and lab ware.

- Food Processing and Medical Device Industries .

- The Food and Drug Administration (FDA) has approved Virgin PTFE for use in the food processing and medical device applications. Due to the thermal stability, aggressive water resistance, and general chemical and biological resistance components of Virgin PTFE numerous food and medical applications associated with human contact.

- Historical Serendipity and The Ongoing Applications of PTFE

- Whatever the case may be, sheer luck or incredible ingenuity, Dr. Roy Plunkett's invention of the polytetrafluoroethylene (PTFE) is chalked up in the historical pages of distinguished scientific innovators such as Thomas Edison, Louis Pasteur, and the Wright Brothers.

- PTFE has revolutionized mankind's progress with In the world of modern industrial, mechanical, aerospace, and medical technology, One of the most challenging applications that has been revolutionized by the advent polytetrefluoroethylene (PTFE) is the nuclear industry.